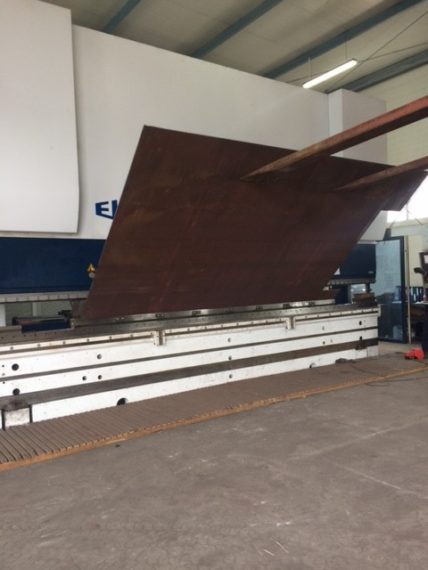

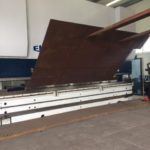

Computerized Numerical Control technology, in other words computer numeric control, is a modern programming method that allows you to eliminate human participation in the production process, and therefore, get rid of any bugs. CNC technology is more and more often referred to as a reliable and trouble-free.

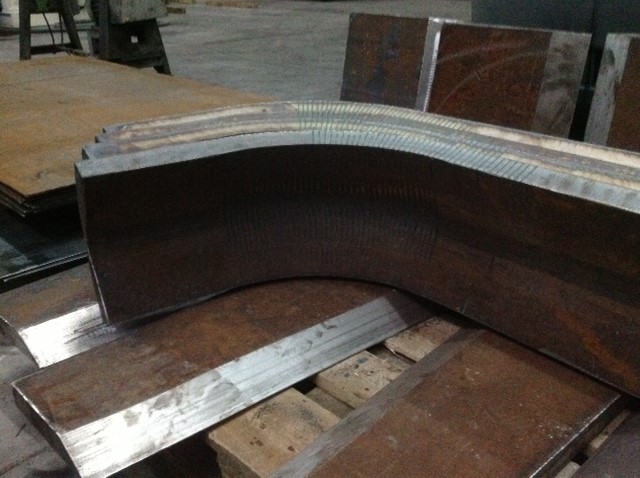

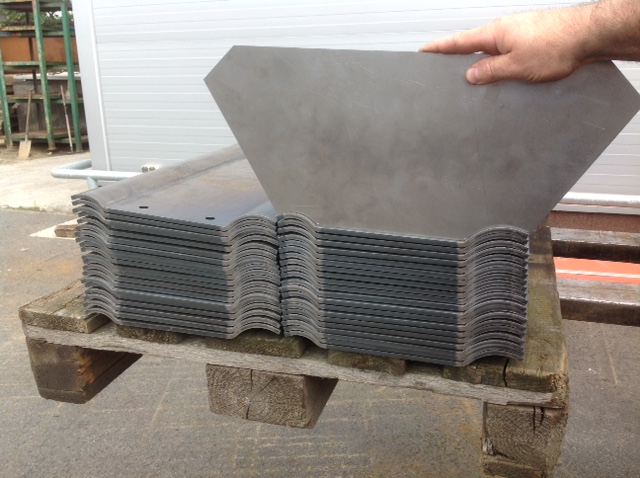

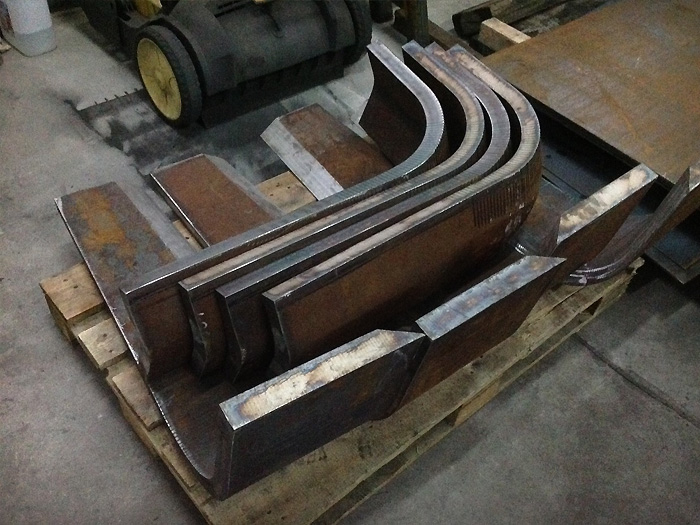

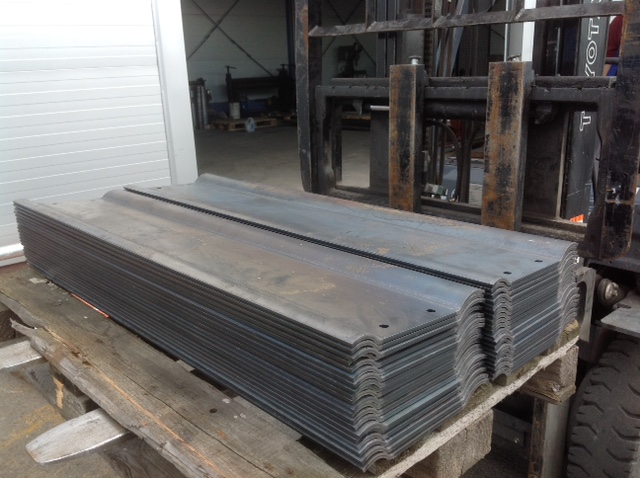

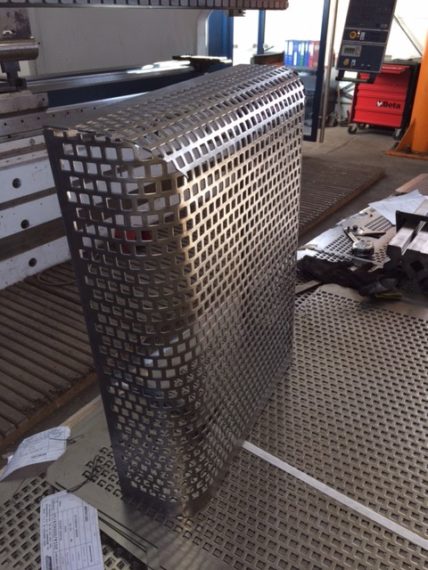

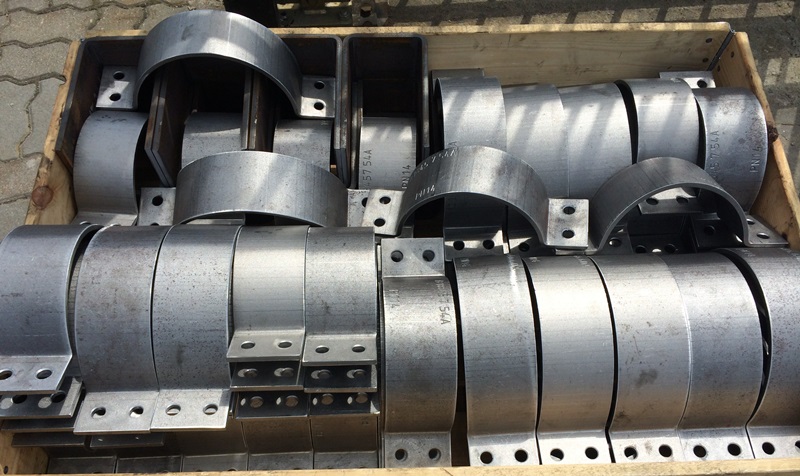

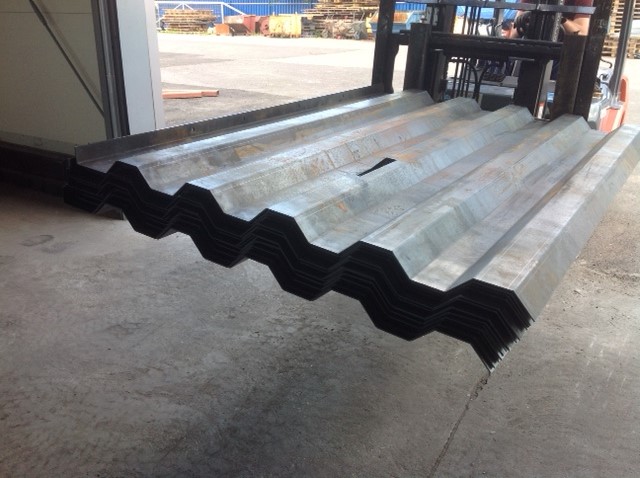

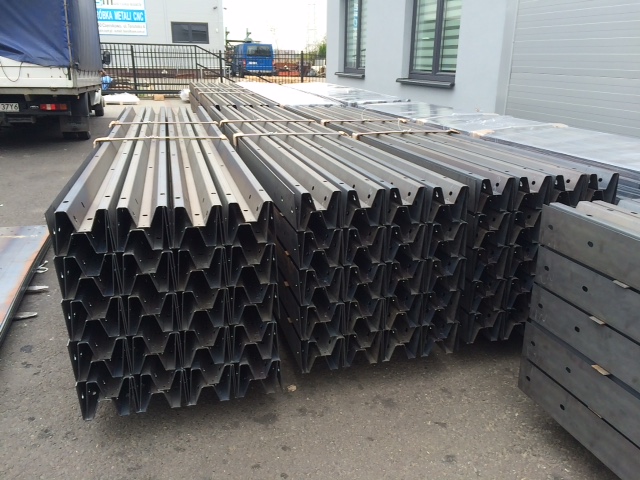

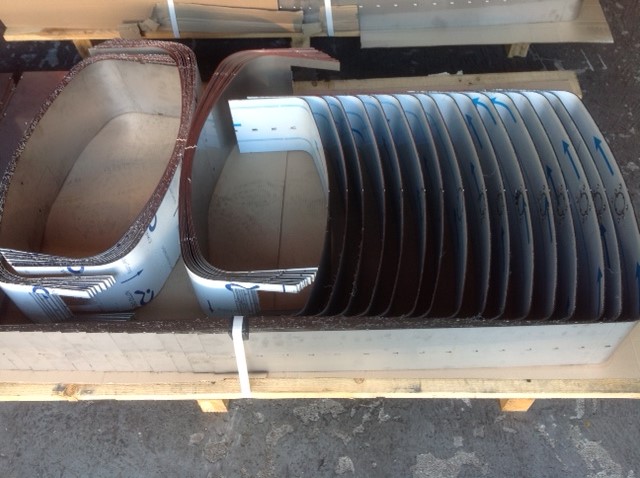

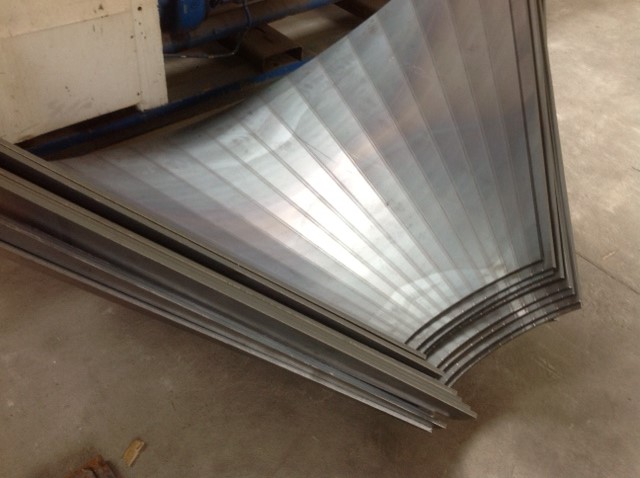

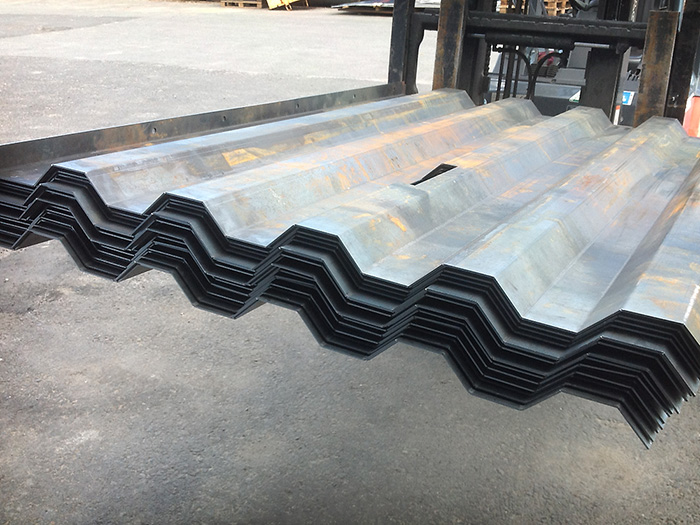

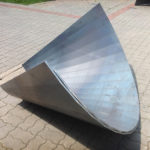

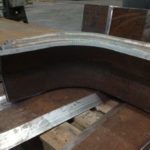

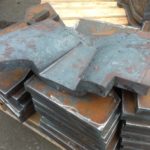

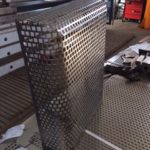

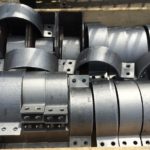

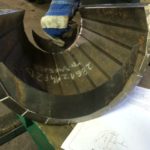

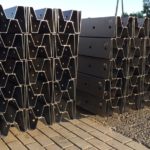

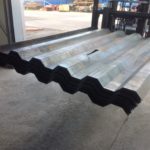

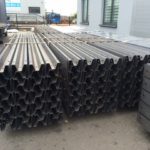

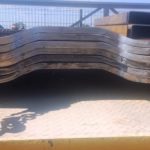

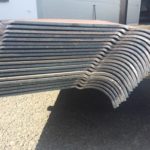

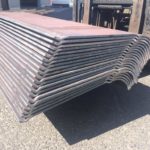

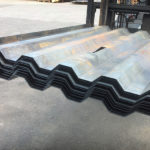

Such extensive automation allows full programming of production, and as a result, the smooth creating a series of repetitive elements. Modern CNC technology is also the best method to obtain even the extremely unusual and complicated shapes.

CNC machining – precision and economy

The use of CNC technology in the metal machining allows you to save both time and money. A fast production process and the low unit cost by implementing large production series, is another of the benefits of using CNC technology.

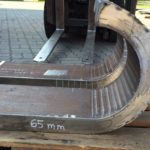

CNC technology is also a guarantee of high quality and enormous precision. Arising shapes during the production process no longer require finishing – the edges are completely smooth!

Not only steel!

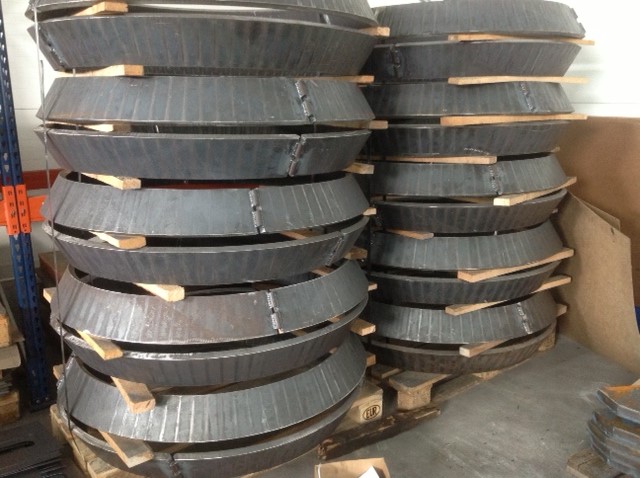

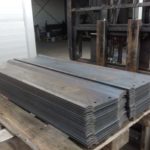

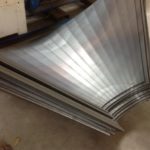

Steel, aluminum, miedź, brass – each of these metals have different properties, so different is the process to its machining. CNC technology can be used for all sorts of materials – aluminum, steel and stainless steel. In addition to this, it is also possible to machine materials of various thicknesses, both thin, standard, and very thick.

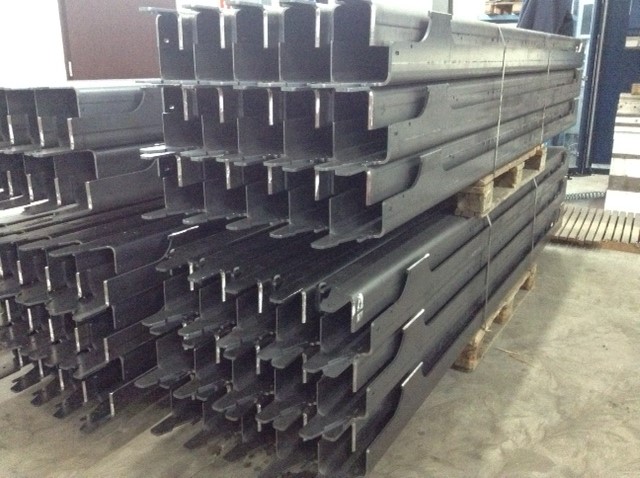

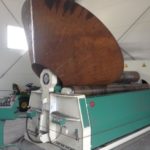

The precision and reproducibility at its best!

In our machine park, we have first of all a modern and advanced equipment. It is thanks to this we obtain fully satisfactory customers. We encourage you to familiarize with the offer of our servies – we provide full professionalism, timeliness of executed orders and expert advice.