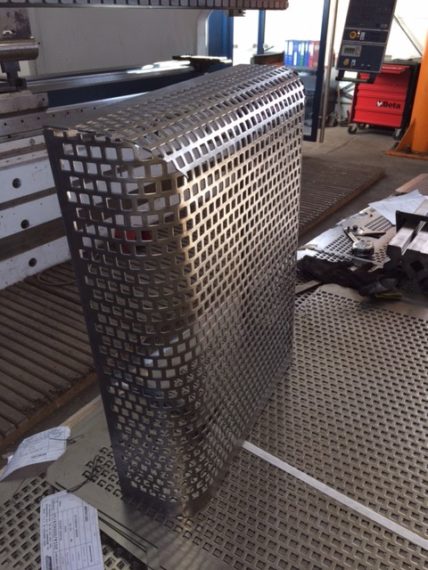

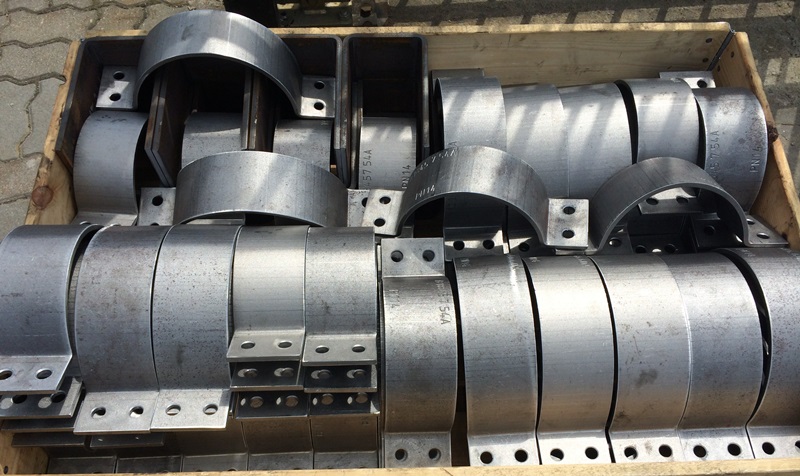

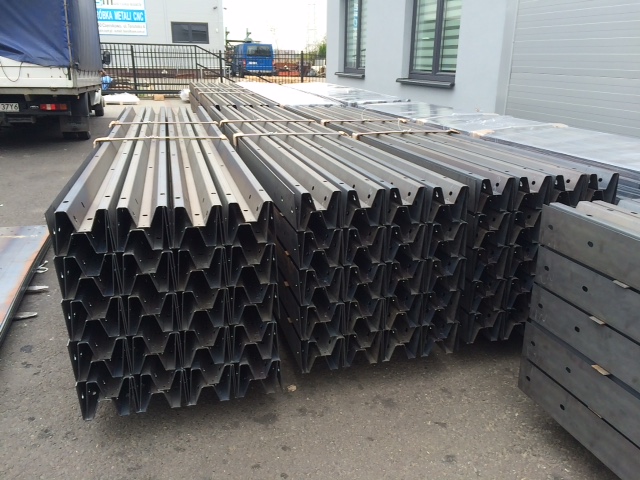

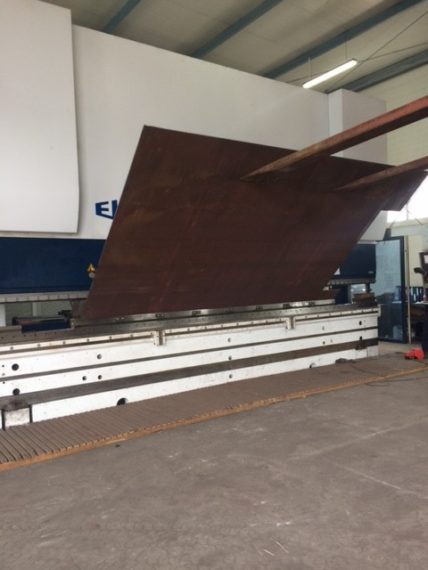

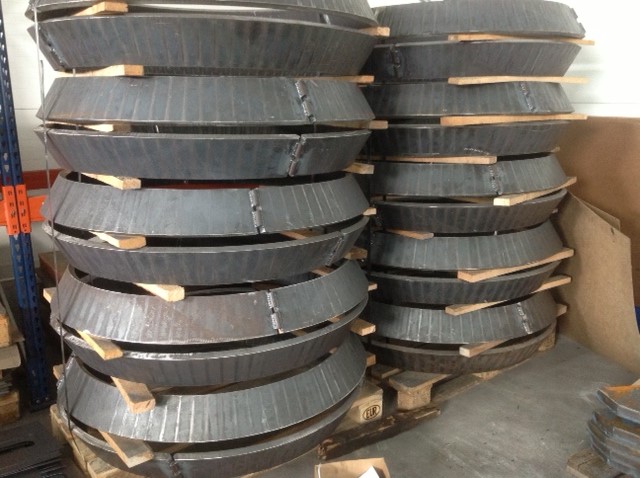

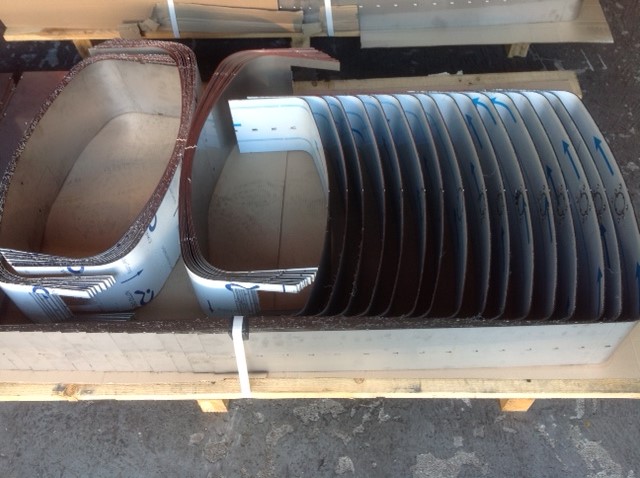

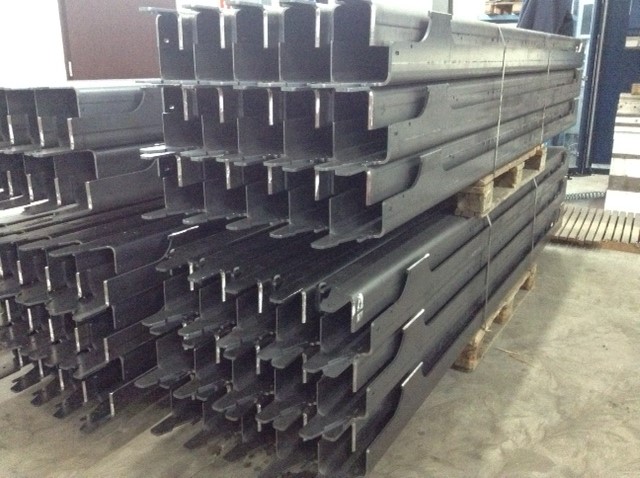

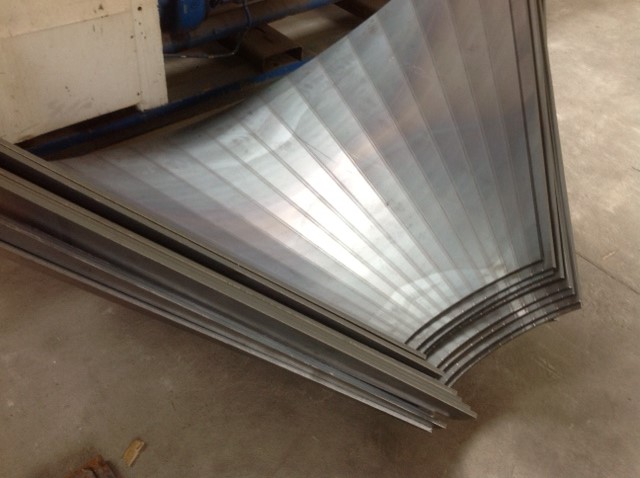

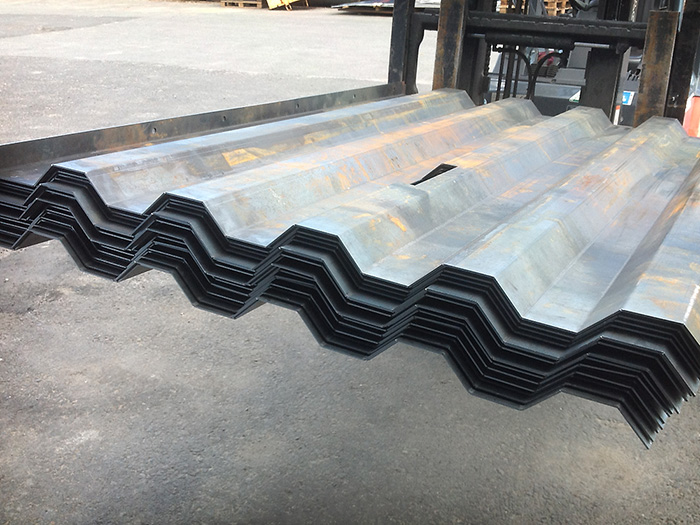

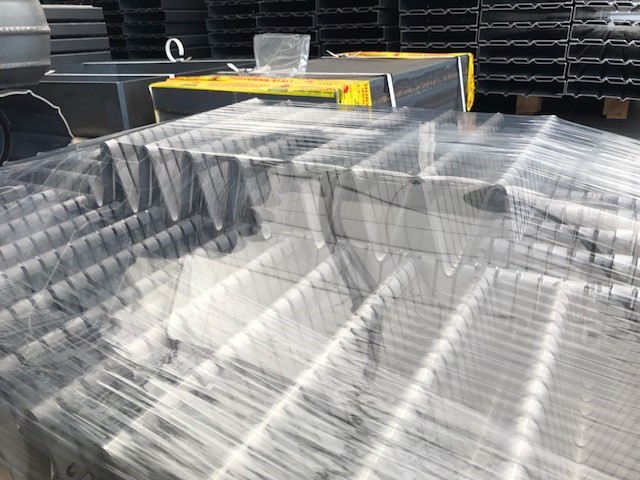

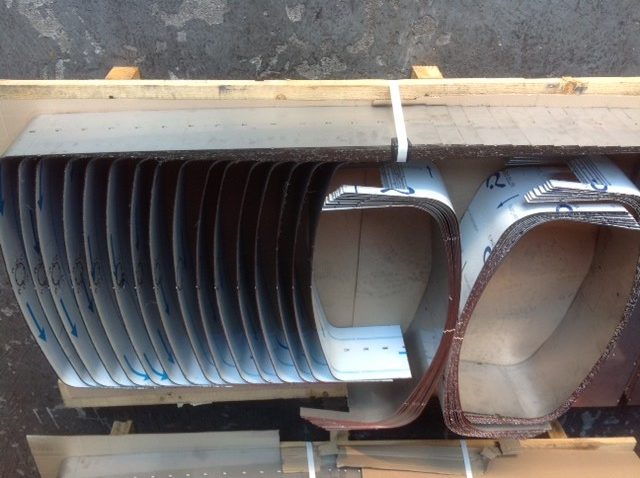

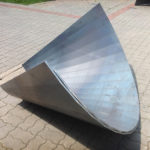

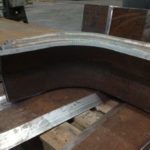

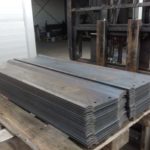

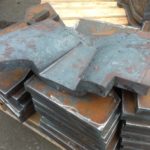

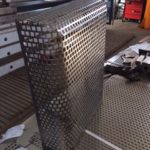

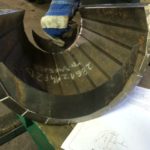

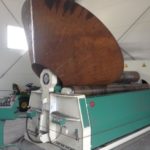

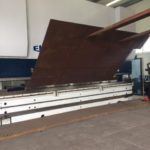

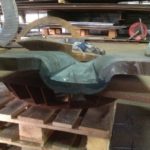

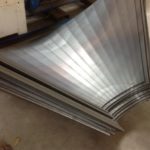

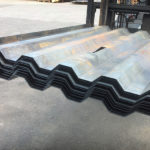

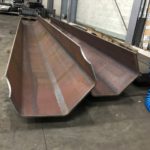

One of the two fundamental services that we offer is the bending of plates and metal using brake presses and CNC technology. Through the use of advanced equipment, we do all kinds of details with precision and also we successfully get their accurate mapping.

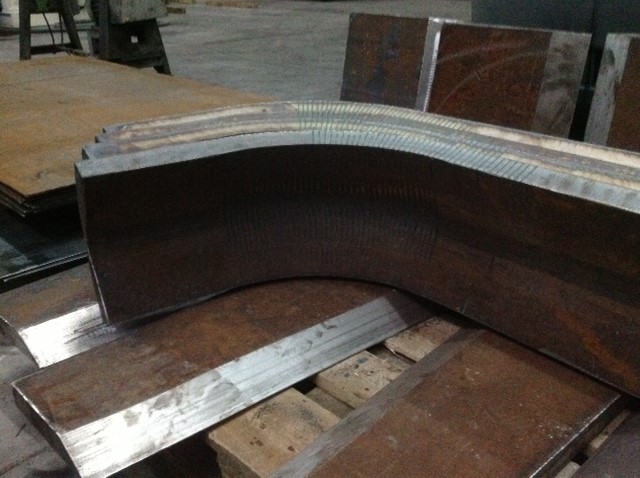

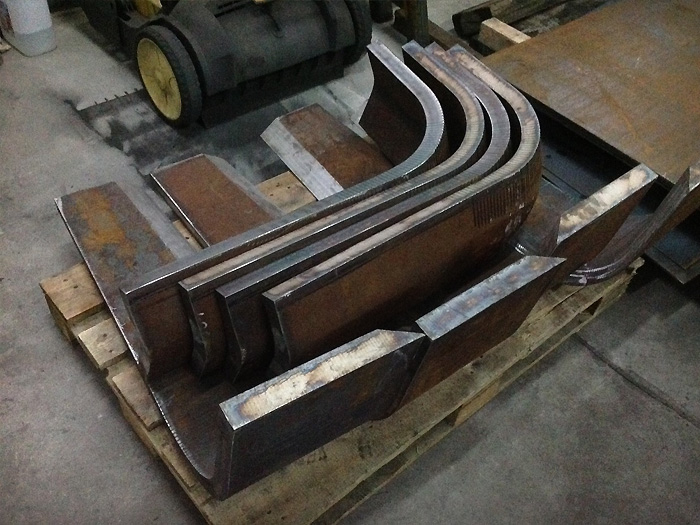

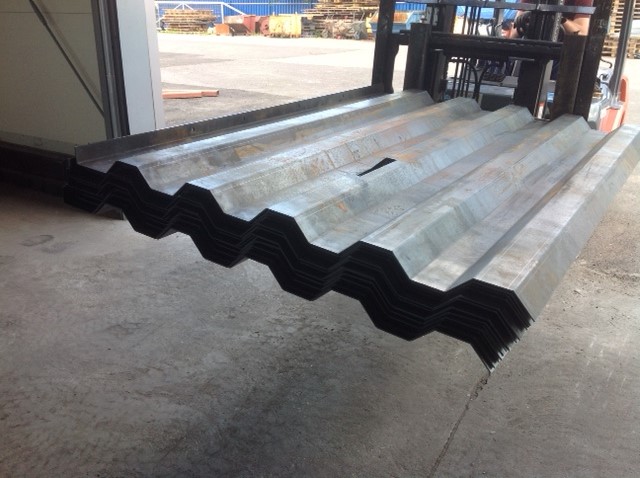

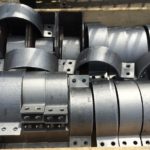

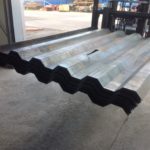

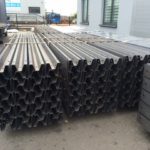

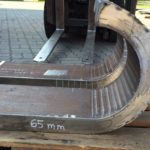

Bending is the proccess of deformation of the material – can be performed on both hot and cold. The most frequently singled out method of bending is bending on presses. The process of bending sheet metal includes three phases – elastic bending, plastic bending and successively sizing. Actions taken during this process are rolling, bending, torsioning, profilling and straightening.

Bending of plates and metal – we know how to do it

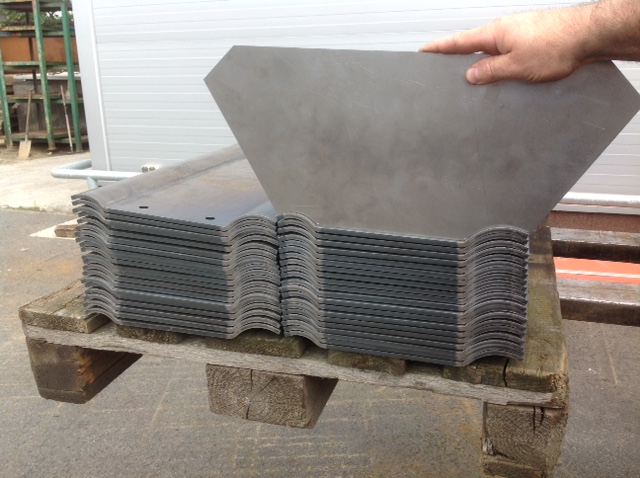

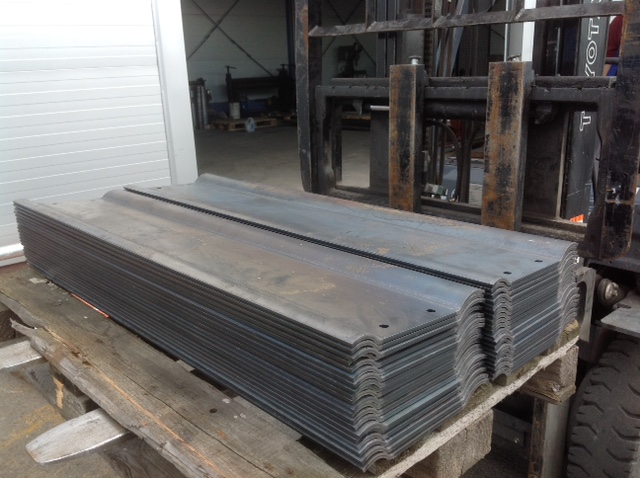

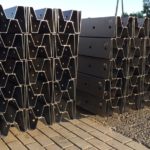

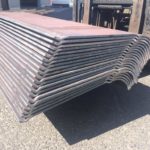

Our extensive machine park located near the city of Toruń is equipped with modern, multifunctional devices, it enables the implementation of even the most non-standard orders. We perform products of any sizes, shapes and materials (aluminium, stainless steel) with full precision. We have precise mapping of the specific parameters, while fully preserving their properties. Orders performed by us are of extraordinary quality and durability.

Bending the sheets – with us is not difficult

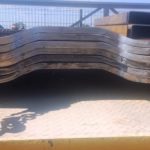

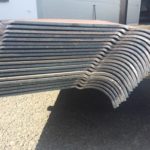

Our firm have at disposal ten machinies, the smallest one is machine of pressure 50 tonnes per lenght of 1250 mm. The biggest one is 1250 tonnes to 8 metres, controlled in eleven CNC axes. It is one of the largest machines in Poland! Its leap is 750mm, and bumper departure is 2500 mm. On presses we perform standard bendings with radial tools, but also with step bending method.

We encourage you to get familiar with our existing implementations. On our website you will also find price list along with specifying the particular services. Welcome!