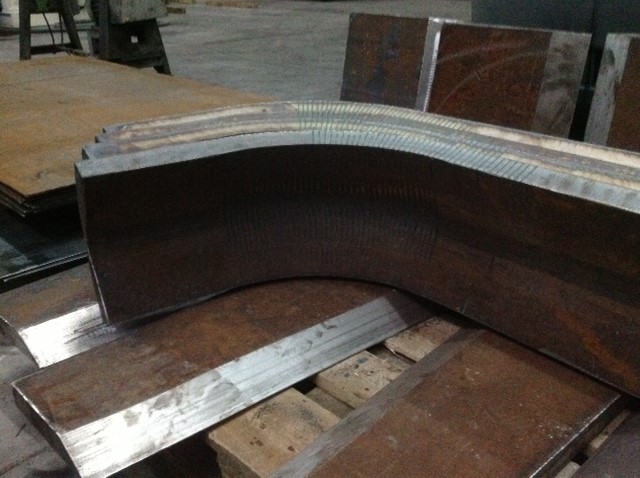

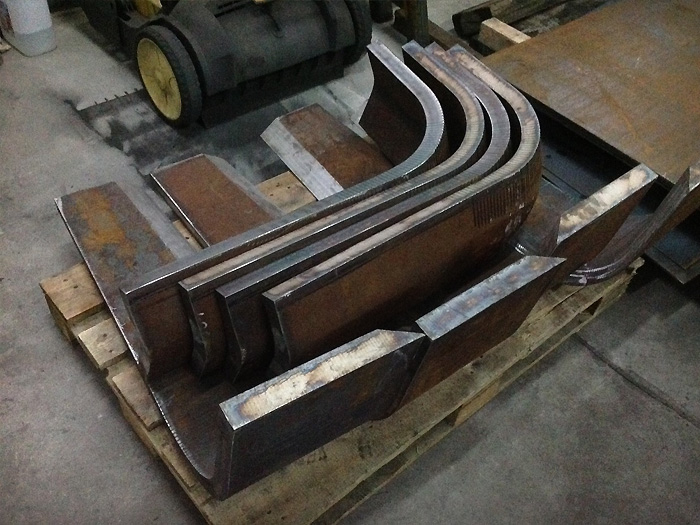

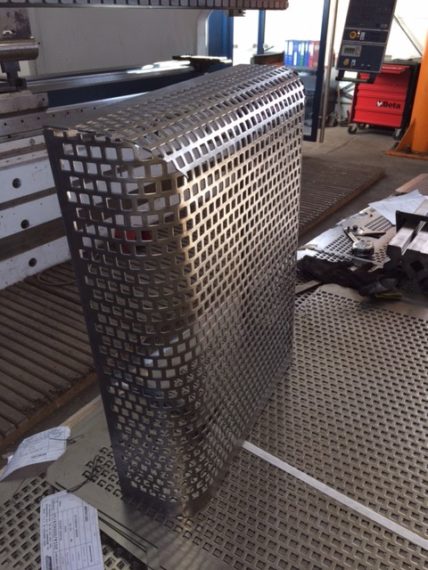

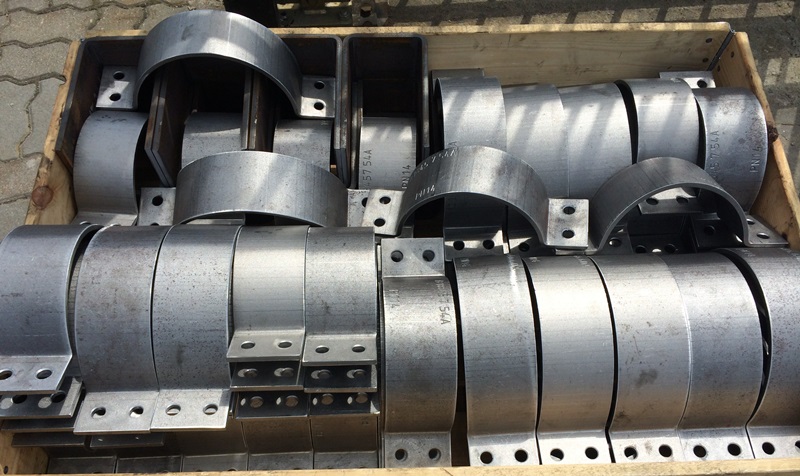

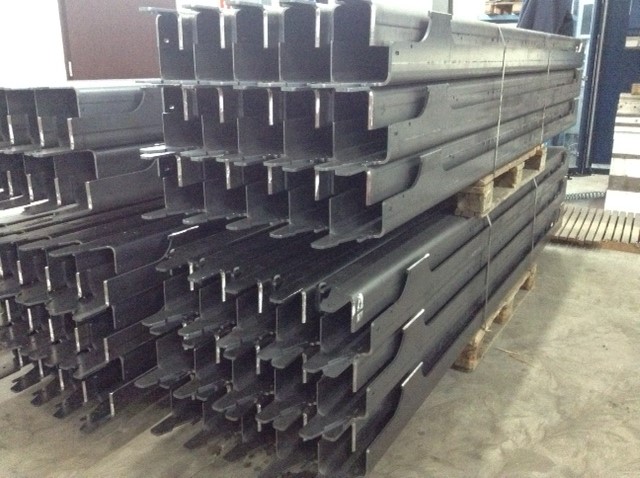

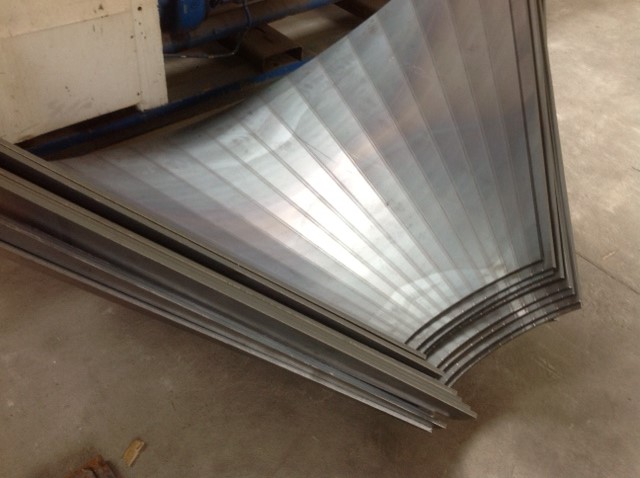

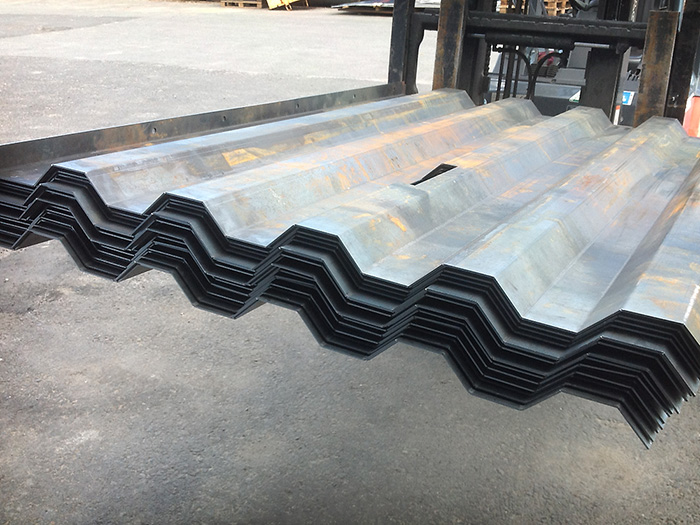

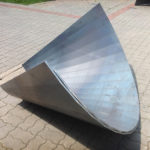

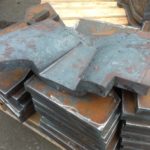

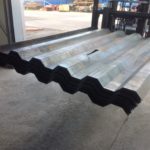

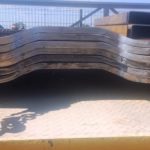

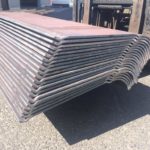

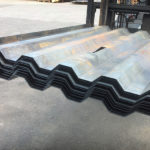

Bending is one of the most used methods of processing of the material, which consists of a permanent change in curvature of the workpiece. According to the obtained results, it is talked about bending, collapsing or straightening. The plastic metal processing is done most often using steel, galvanized steel, stainless steel or aluminum.

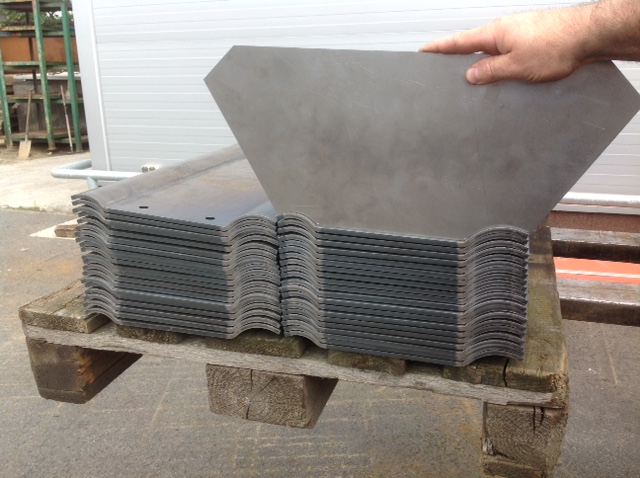

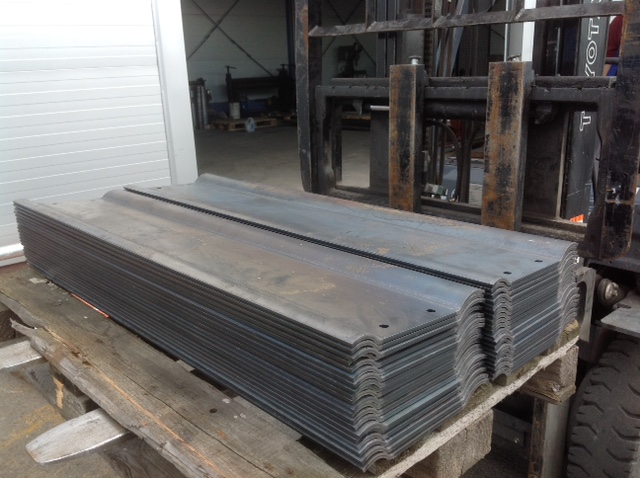

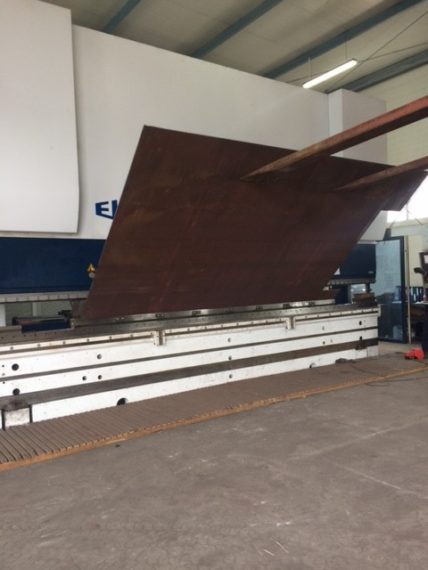

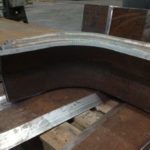

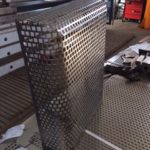

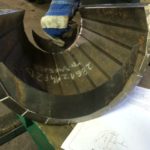

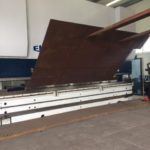

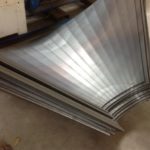

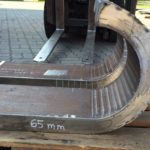

One of the ways used to bending is cold forming. In this case the press brakes, which was based on a modern CNC technology. Such a way is efficient and cost effective – allows you to to obtain the finely crafted items, as well as repetitive, precisely mapped the angle of bending.

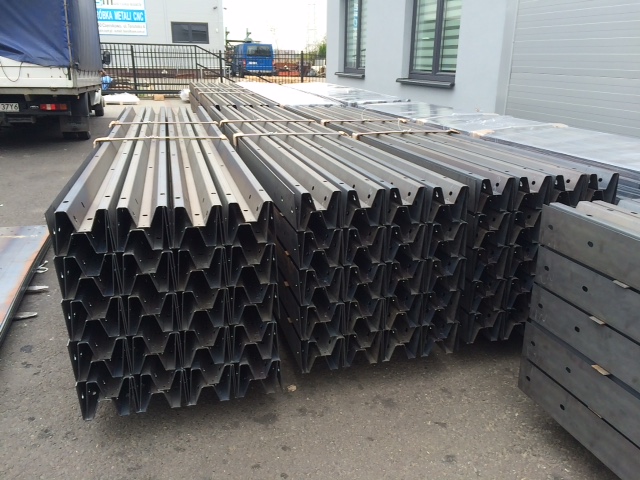

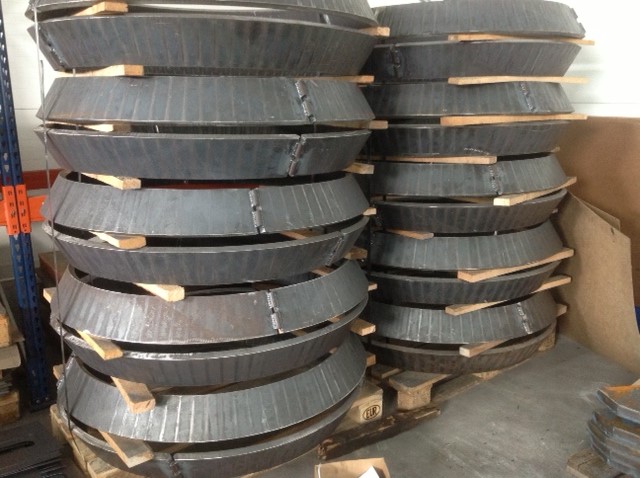

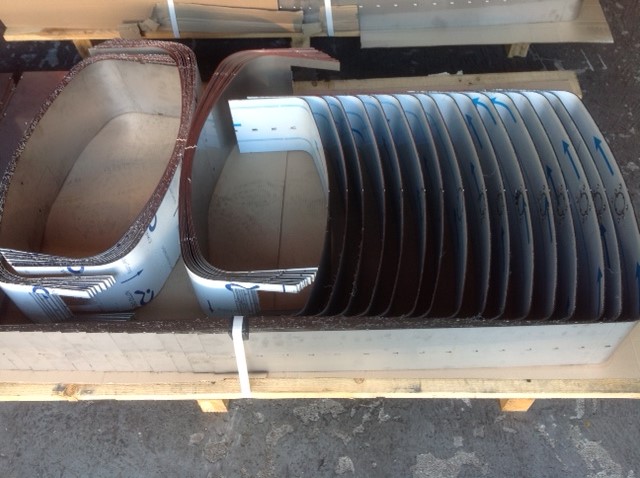

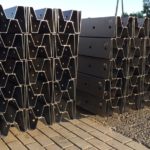

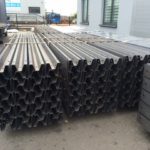

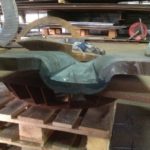

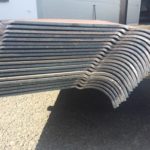

Modern devices have a number of advantages. In addition to receiving even very complicated, and one hundred percent of repetitive shapes, the use of CNC technology using press brakes allows you to significantly reduce the time of the production process, and also get a large series of elements with low unit cost. The result is a freely selectable number of identical items – from a single prototype to the whole series.

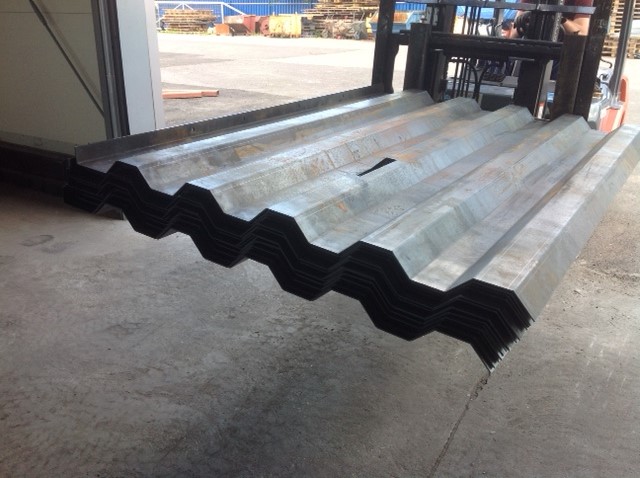

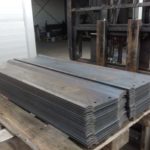

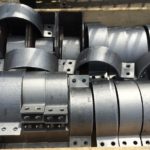

Press brake perfectly copes with both thin and thick sheets of metal. Technologically advanced equipment, compared to the hitherto used devices, is truly revolutionary. Modern, digitally controlled machines significantly reduce human participation in the production process. Equipped with guides and maintenance-free bearings allow for automatic transfer of material between the successive stages of the process.